TS-STRUCTURE

TS-STRUCTURE

ALLU TS structure enables two different fragment sizes from the same unit. Fragment size estimation is based on the distance set by the screening comb.

The ALLU TS structure allows you to adapt your bucket for your screening needs quickly and effortlessly, giving you the ability to have more versatile processing.

The TS structure has been developed with a self-cleaning system allowing for the best possible capacity even with wet material. We call this innovative design a non-clogging system and is available across our entire TS range.

TS Screening Blades

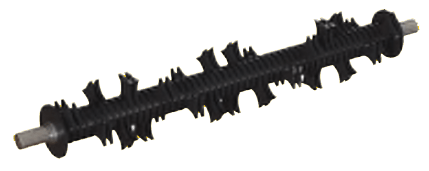

TS Axe Blades

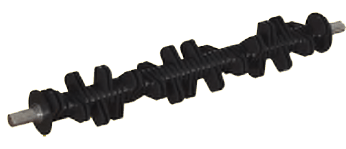

Axe Blade

An ideal blade model for applications that require shredding and/or crushing soft materials, e.g., compost, bio waste, and bark.

ALLU Transformer equipped with TS Axe blades will enable a homogenous end product, even with the most challenging materials.

SPECIFICATIONS

| Tn | Lbs | Tn | m³ | Lpm | Kg | |

| DL 2-12 TS | 7-12 | 1190 | 3-8 | 0,5/0,6 | 40-70 | 540 |

| DN 2-12 TS | 12-28 | 2425 | 6-14 | 0,6/0,7 | 95-160 | 1100 |

| DN 2-17 TS | 15-28 | 3042 | 7-14 | 0,9/1,0 | 95-160 | 1380 |

| DN 3-12 TS | 16-28 | 3109 | 7-14 | 1,0/1,2 | 125-160 | 1410 |

| DN 3-17 TS | 20-28 | 3946 | 9-14 | 1,3/1,5 | 160-200 | 1790 |

| DH 3-12 TS | 18-45 | 4343 | 8-30 | 1,0/1,2 | 190-315 | 1970 |

| DH 3-17 TS | 22-45 | 5423 | 10-30 | 1,3/1,5 | 190-315 | 2460 |

| DH 3-23 TS | 26-45 | 6327 | 14-30 | 1,7/2,0 | 190-315 | 2870 |

| DH 4-12 TS | 22-45 | 4938 | 10-30 | 1,2/1,4 | 190-315 | 2240 |

| DH 4-17 TS | 27-45 | 6482 | 14-30 | 1,8/2,1 | 190-315 | 2940 |

| DH 4-23 TS | 32-45 | 7430 | 16-30 | 2,3/2,7 | 190-315 | 3370 |

Options

| TS 16/32 blade | TS Standard blades | Extra Side | |

| TS 25/50 blade | TS Axes blades | Directional Valve | |

| TS 35 blade | For wet, frozen, and different soils | Drain oil eliminator | |

| Drain line relief valve | |||

| ALLU Data Reporting System |

Main Applications

Backfill separation or screening technology plays a crucial role in waste material handling by improving material quality, reducing contamination, minimizing waste volume, enhancing safety, and facilitating recycling and resource recovery. It contributes to more sustainable waste management practices and supports environmental and regulatory compliance.

Backfill separation or screening is an essential component of successful composting operations. It improves feedstock quality, promotes efficient decomposition, reduces processing time, and results in a higher-quality compost product that is beneficial for soil health and environmental sustainability.

Backfill separation is a critical practice in pipeline projects, contributing to the reliability, safety, and cost-effectiveness of pipeline infrastructure installation and maintenance. It supports proper pipeline protection, minimizes the risk of damage, aids in erosion control, ensures environmental compliance, and enhances overall project efficiency.

A screening bucket can significantly enhance field bark-crushing operations by improving material separation, enhancing product quality, reducing contaminants, and increasing overall efficiency. It supports resource recovery, cost savings, and environmentally responsible practices, making the processed bark material more versatile and marketable for various applications.