DL-SERIES

DL-Series

ALLU Transformer DL are screening buckets for compact base machines and are suitable for excavators max. 12Tn (11.8 US Tn), skid steer loaders, tractors, and backhoe loaders.

The DL bucket is the unique top screen where the screening blades spin between the top screen combs. The space between the combs defines the end material size. These screening combs carry most of the material weight to ensure the drums and bearings take on less impact and load. This construction is clog-free and maintains good capacity even with wet materials.

Transformer DL-series attachments are perfect for screening topsoil, peat, and compost. They’re also ideal for landscaping and padding on smaller cable and pipeline job sites.

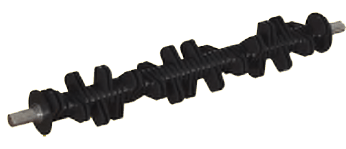

TS Screening Blade

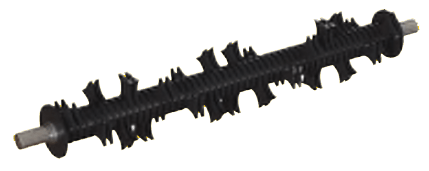

TS Axe Blade

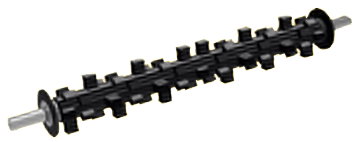

X50 Blade

SPECIFICATIONS

| Tn | Lbs | Tn | m³ | Lpm | Kg | |

| DL 2-09 | 4-12 | 948 | 2-8 | 0,4/0,5 | 40-70 | 430 |

| DL 2-12 | 7-12 | 1190 | 3-8 | 0,5-0,6 | 40-70 | 540 |

| DL 2-17 | 9-12 * | 1532 | 4-8 | 0,8-0,9 | 40-70 | 695 |

Options

| Standard blades | Extra Side | |

| Axe blades | Stabilization blade | |

| Blade cassettes (TS15, TS25 and X50) |

Main Applications

Backfill separation contributes to the success of landscaping projects by improving soil quality, ensuring proper grading, preventing erosion, supporting healthy plant growth, and enhancing the aesthetics and functionality of outdoor spaces. It is an essential practice for achieving long-lasting and attractive landscaping results.

The screening bucket can help ensure the quality and suitability of topsoil for various applications, from gardening and landscaping to construction and horticulture. It helps create a fertile, clean, uniform topsoil that supports healthy plant growth and enhances outdoor spaces' aesthetic and functional aspects.

Backfill separation and screening can significantly contribute to the efficiency, quality, and sustainability of agricultural processing. These processes help produce high-quality soil, seeds, and organic amendments, enhance crop production, and promote environmentally responsible agricultural practices.

Backfill separation or screening is an essential component of successful composting operations. It improves feedstock quality, promotes efficient decomposition, reduces processing time, and results in a higher-quality compost product that is beneficial for soil health and environmental sustainability.

Backfill separation or screening contributes to better aeration in soil and compost management by preparing materials for more effective aeration processes. It facilitates uniform aeration, contaminant removal, reduced compaction, and enhanced decomposition, leading to improved soil structure, healthier plants, and higher-quality compost products.